Anodising

As aluminium “corrodes” it produces a loose dry white powder, aluminium oxide. The anodising process artificially produces this film but as a hard, uniform, dense wear resistant surface. The two most common ways to produce this film are by passing a DC current through parts immersed in an electrolytic solution usually either sulphuric acid or chromic acid. (Recently sulphuric acid mixed with Tataric acid or Boric acid has been used as a method of replacing the less environmentally acceptable Chromic acid solution). The passing of the current liberates high volumes of Oxygen at the surface of the aluminium thus aiding controlled formation of the oxide layer. These processes do not produce a coating but are a conversion of the surface aluminium to aluminium oxide and are therefore metallurgically bonded.

Both the Chromic and sulphuric acid methods produce a dense layer, which because it is porous, requires a subsequent sealing process to close the pores and prevent further natural attack on the aluminium. Sealing is carried out by immersing the component in near boiling de-mineralised water, which if required can have small quantities of other chemicals, such as Nickel acetate or sodium dichromate to further enhance corrosion resistance. Before sealing, immersion in specially formulated dyes can be carried out, the open pores soak up the dye which will then be locked in by the sealing process, this can produce very attractive finishes but will depend on the thickness of the anodised film as the thinner the film, the less dye will be absorbed.

A major benefit of anodising is that because the oxide film is electrically resistant, the film is distributed across the component very evenly as when the film starts to grow that area becomes more resistive until all other areas on the component have achieved the same thickness thus equalising the relative resistivity and ensuring even growth over the whole component

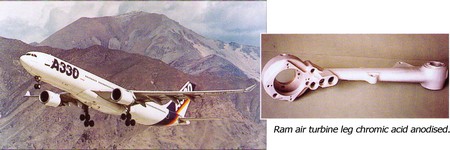

Chromic Acid Anodising

|

This method produces comparatively thin but dense oxide films which are usually dark grey in colour; they have very good corrosion resistance but are not really suited to subsequent dyeing as they are only 2-5microns thick. However, as they are thin they do not affect close tolerances so are used extensively in the aerospace and defence industries. If left unsealed they are an excellent base for subsequent painting operations as the first coat of paint soaks in to the pores.

The thin film also reduces the possibility of fatigue fracture on the component, furthermore unlike Sulphuric acid, Chromic acid protects rather than attacks aluminium so any residual solution that may have been trapped in cracks, pores or folds will not corrode the component, these two attributes make Chromic acid anodising ideal for critical components in the aerospace and defence sectors.

A further benefit of the chromic process is that the chromic solution is extremely searching and will seep in to even the smallest of flaws and as it is also a brownie/orange colour there will be a stain apparent around the flaw thus, allowing the process to act as a non destructive flaw detection method. This test is used extensively on defence related products.

Considered a more “environmentally friendly” process to chromic acid anodising, this process offered by Ashton & Moore Ltd., can mimic the thin anodised layer of the chromic process whilst using Sulphuric acid instead. Although, currently it still requires the use of hexavalent chrome at very low levels for the final sealing operation. This process is already accepted as an alternative to chromic acid anodising in some areas of the aerospace sector (eg. by Claverham) and is seriously being considered by others.

This method can produce much thicker films than the chromic process, and is generally used in corrosion resistance, general engineering, or decorative applications, Aluminium can be chemically or mechanically polished, satin etched or even left in its natural state prior to anodising. Thus, combined with the ability to accept dye, sulphuric anodised films offer a wide variety of visual finishes.

Sulphuric anodising can be found in almost every walk of life wherever aluminium is used and examples of this process can be seen on domestic cookware, hand tools, fascias for computers and televisions, automotive trim etc.

Sulphuric acid anodising may also be used to apply anodic films on Titanium. These films are relatively thin but prevent natural oxidation, provide an extra “Key” for subsequent coatings and can also be used to colour the surface of the component.

Tartaric sulphuric acid anodising

Like Thin film Sulphuric acid anodising this is considered a more “environmentally friendly” option to chromic acid anodising and is now the preferred option for Airbus and offered by Ashton and Moore Ltd. This is despite the fact that it currently still requires a hexavalent chromic seal (like Thin film sulphuric anodising), unless the surface is subsequently painted.

Exacting engineering requirements now require that specific areas of components should not be coated. Although masking for anodising is particularly challenging, Ashton & Moore has developed their own range of masking media to meet the most demanding requirements. When combined with the use of bungs and pre-cut masking media, etc. this permits us to achieve remarkably intricate, accurate and repeatable results on a production scale.